The graduate program in mechanical sciences has established an articulated and planned policy for the creation and modernization of its laboratories. This has been achieved by gathering funding associated with research projects approved by Sectorial Funds in the areas of Oil & Gas and Energy (CT-Petro, CT-ENERG), which are related to companies and agencies such as Eletronorte, CTEEP, CELG, Petrobrás, FINEP, CNPq, and CAPES. The research groups of our program have acted towards gathering funding to nucleate and support modern and well-equipped facilities and laboratories, which has provided an environment for high-level education and research. Professors and students also have access to the best scholarly journals by the Portal Periodicos, which is supported by the Brazilian Agency for Higher Education – CAPES, in addition to effective administrative support. The combination of these factors yields a modern infrastructure for the development of experimental, theoretical, and computational research activities in the areas of Fluid Mechanics, Solid Mechanics, Thermal Engineering, Mechanical Vibrations, and Dynamical Systems.

Research line: Fatigue, Fracture, and Materials

Laboratory of Mechanical Tests

This laboratory is dedicated to research in fatigue and fracture of engineering materials and components. The infrastructure of the lab is comparable to those available in the best world’s research institutions in the area. We have expertise in various types of mechanical tests, including high-complexity fatigue experiments (even in a global scenario) such as fretting fatigue tests of wires of overhead conductors, fretting fatigue involving multiple actuators, and axial-torsional fatigue tests, the last two also at high temperature.

This laboratory is dedicated to research in fatigue and fracture of engineering materials and components. The infrastructure of the lab is comparable to those available in the best world’s research institutions in the area. We have expertise in various types of mechanical tests, including high-complexity fatigue experiments (even in a global scenario) such as fretting fatigue tests of wires of overhead conductors, fretting fatigue involving multiple actuators, and axial-torsional fatigue tests, the last two also at high temperature.

Equipment

- 2 axial-torsional MTS 809 machines with a capacity of 100 kN/1100 N·m;

- 2 axial MTS 810 machines with a capacity of 100 kN;

- 1 axial MTS Landmark 370 machine equipped with a 5 kN-load cell;

- 1 fretting fatigue testing system with 4 independent actuators, that is capable to apply a fatigue force of up to 250 kN, a tangential force of up to 100 kN, and contact normal force of up to 15 kN;

- 1 fretting fatigue test machine for wires of overhead conductors with a capacity to apply a fatigue force of up to 25 kN, a tangential force of up to 15 kN, and contact normal force of up to 5 kN;

- 1 reduced-scale apparatus for fatigue testing of mooring chains under out-of-plane bending;

- MTS model 653 furnace for axial-torsional testing at high temperature (up to 1400 °C),

- Heating system for fretting fatigue tests at high temperatures (up to 850 °C).

Expertise to conduct the following tests:

- Tensile test

- Axial/torsional strain-controled fatigue tests (strain-life curve)

- Axial/torsional stress-controlled tests (stress-life curve)

- Fatigue crack propagation tests (da/dN x ΔK curve)

- Fracture toughness test

- Fretting fatigue test

- Monotonic and fatigue tests at high temperature

Laboratory of Fatigue and Structural Integrity of Overhead Conductors

This laboratory is dedicated to investigations in the areas of fatigue and dynamic characterization of overhead conductors. Funding has come from the transmission and distribution companies of the energy sector. The infrastructure of the laboratory has three 60 m-spans with sophisticated control and monitoring system that enables us to perform fatigue and self-damping tests with a high level of accuracy. It is the only laboratory of this type in the Southern Hemisphere, and perhaps the one with the best instrumentation in the world. The laboratory can perform tests at high temperatures and on different types of conductors and suspension clamps. The experimental work in this laboratory has been accompanied by complex numerical simulations of the conductor-clamp system in high-performance workstations.

This laboratory is dedicated to investigations in the areas of fatigue and dynamic characterization of overhead conductors. Funding has come from the transmission and distribution companies of the energy sector. The infrastructure of the laboratory has three 60 m-spans with sophisticated control and monitoring system that enables us to perform fatigue and self-damping tests with a high level of accuracy. It is the only laboratory of this type in the Southern Hemisphere, and perhaps the one with the best instrumentation in the world. The laboratory can perform tests at high temperatures and on different types of conductors and suspension clamps. The experimental work in this laboratory has been accompanied by complex numerical simulations of the conductor-clamp system in high-performance workstations.

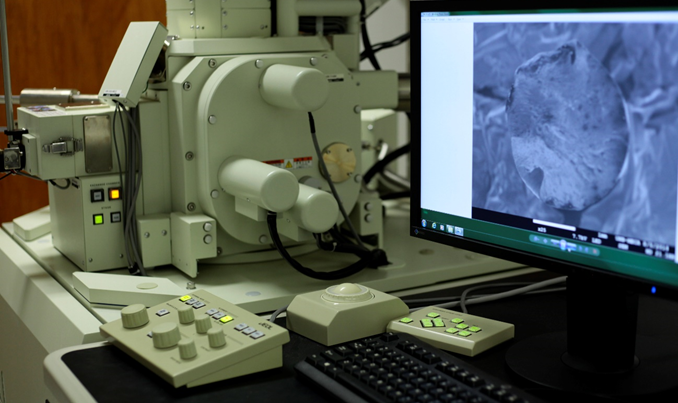

Laboratory of Scanning Electron and Confocal Laser Microscopy

The laboratory is equipped with a JEOL JSM 6610 scanning electron microscope (SEM) with an acceleration voltage of 30 kV, resolution of 3 nm, magnification of up to 300.000 x, and capability to perform energy dispersive X-ray (EDS) microanalysis.

The laboratory is equipped with a JEOL JSM 6610 scanning electron microscope (SEM) with an acceleration voltage of 30 kV, resolution of 3 nm, magnification of up to 300.000 x, and capability to perform energy dispersive X-ray (EDS) microanalysis.

The laboratory has an OLYMPUS LEXT OLS 4000 laser confocal microscopy capable of taking high-resolution 3D images and micro-geometric measures such as roughness, volume, and area. Magnification ranges from 108 to 17,280 x. It is possible to scan the sample at several x-y planes and different heights to build a tridimensional image of the object.

Laboratory of Material and Metallurgy

This laboratory, which has an area of approximately 100 m2, is composed of a metallographic preparation room, optical microscope, universal hardness testing machine, microhardness tester, pendulum impact, heat treatment furnaces for temperatures up to 1100 °C, and sintering furnace for temperatures up to 1700 °C and high vacuum.

The laboratory also has a microabrasion testing machine, which has been used for microabrasive wear research. The contact system is made of a rotating ball, an abrasive suspension fluid, and a specimen. The experimental configuration allows controlling the rotational speed of the ball, the sliding distance between the ball and the specimen, and the concentration and flow rate of the abrasive fluid. The analysis of the craters (wear marks) allows characterizing the abrasive wear behavior of a material.

Laboratory of Biomass Technologies

This laboratory provides support to research on conversion, characterization, treatment, and applications of vegetable biomass aiming at the development of new materials and fuels. The materials derived from renewable sources can be used to obtain biodegradable polymers, reinforced composites with natural fibers, and renewable fuels.

The laboratory is divided into two spaces: the instrumental analysis room has 15 m2 and is fully equipped with thermal and chemical analyzers, and another room has 20 m2 and is used to develop activities related to the treatment of vegetable biomass and the preparation of polymers, composites, and biofuels. The laboratory is equipped with a simultaneous thermal analyzer (TGA, DTA, and DSC), Fourier Transform Infrared Spectrometer, Gas chromatographer, heating mantle, ultrasonic bath, water bath, pH meter, casting heater, centrifuge, rotary evaporator, muffle furnace, oven, basic laboratory glassware and other more particular, such as Soxhlet extractor and viscometer.

To find more information, look at the blog https://sandraluz-unb.blogspot.com and YouTube channel https://www.youtube.com/channel/UCaENfLdZeZMdSRXXILZE1KA?view_as=subscriber

Research line: Energy and environment

Combustion Engines Test Facility

This laboratory has two dynamometers with full instrumentation for engine tests of up to 300 cv. Research work has traditionally involved Otto and Diesel engines operating with liquid and gas fuel (gasoline, diesel oil, alcohol, and gas). Currently, another two research lines have been investigated: tests of engines operating with gases derived from gasifiers and biodiesel. The laboratory also has two gas micro-turbines benches for operation with different fuels and studying of the combustion process. One of the benches is a turbo-compressor with a combustion chamber equipped with a swiller generation system. The second has a transparent combustion chamber of the Lean Premixed and Pressurized Combustor type. This unity has adjustable blades swillers to enable control of the vorticity intensity in the combustion chamber.

This laboratory has two dynamometers with full instrumentation for engine tests of up to 300 cv. Research work has traditionally involved Otto and Diesel engines operating with liquid and gas fuel (gasoline, diesel oil, alcohol, and gas). Currently, another two research lines have been investigated: tests of engines operating with gases derived from gasifiers and biodiesel. The laboratory also has two gas micro-turbines benches for operation with different fuels and studying of the combustion process. One of the benches is a turbo-compressor with a combustion chamber equipped with a swiller generation system. The second has a transparent combustion chamber of the Lean Premixed and Pressurized Combustor type. This unity has adjustable blades swillers to enable control of the vorticity intensity in the combustion chamber.

Laboratory of Heat Transfer

The laboratory of heat transfer has a variety of equipment and sensors to carry out applied and fundamental research, including systems for temperature and pressure data acquisition, a thermal chamber, thermal baths, calorimeters, sources of voltage and current, flow rate sensors for liquids and gases, among others. Experiments involving natural convection, mixed convection, and thermal accumulation in BioPCM’s have been conducted in the laboratory. Support is also given to other facilities, such as the assembling of hot-wire anemometry probes.

The laboratory of heat transfer has a variety of equipment and sensors to carry out applied and fundamental research, including systems for temperature and pressure data acquisition, a thermal chamber, thermal baths, calorimeters, sources of voltage and current, flow rate sensors for liquids and gases, among others. Experiments involving natural convection, mixed convection, and thermal accumulation in BioPCM’s have been conducted in the laboratory. Support is also given to other facilities, such as the assembling of hot-wire anemometry probes.

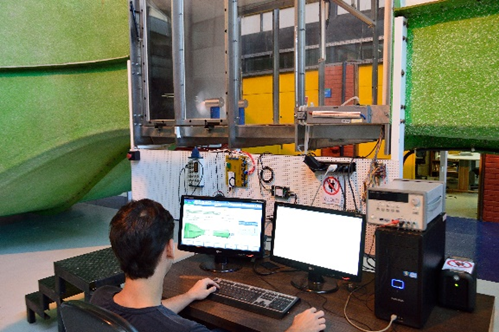

Platform for Testing of Hydrokinetic Devices (Wind Tunnel)

The Energy and Environment Lab is equipped with a wind tunnel facility to carry out experiments on models of horizontal-axis free turbines and possible others. Aerodynamics and Fluid Mechanics studies. The wind tunnel test section has dimensions of 1.2 m height, 1.2 m width, and 2 m length. The flow speed inside the tunnel may be set between 1 and 20 m/s. The free turbulence intensity is less than 1% at the test section inlet and the boundary layer in the preferred position for turbine testing is about 8mm. The wind tunnel is fully instrumented with Pitot tubes, a hot-wire anemometer system, 3D automatic probe positioning system, variable speed controllable dynamometers for torque measurements in turbine rotors, and a smoke source for flow visualization. All instrumentation is integrated and operates automatically.

The Energy and Environment Lab is equipped with a wind tunnel facility to carry out experiments on models of horizontal-axis free turbines and possible others. Aerodynamics and Fluid Mechanics studies. The wind tunnel test section has dimensions of 1.2 m height, 1.2 m width, and 2 m length. The flow speed inside the tunnel may be set between 1 and 20 m/s. The free turbulence intensity is less than 1% at the test section inlet and the boundary layer in the preferred position for turbine testing is about 8mm. The wind tunnel is fully instrumented with Pitot tubes, a hot-wire anemometer system, 3D automatic probe positioning system, variable speed controllable dynamometers for torque measurements in turbine rotors, and a smoke source for flow visualization. All instrumentation is integrated and operates automatically.

Laboratory of Solar Energy

This laboratory aims to establish relations between solar resource and the available conversion technologies using solar resource measures, experimental prototypes, and modeling of conversion systems.

The laboratory has a full solarimetric station installed on the roof of the Energy and Environmental Lab building that is capable to independently measure horizontal global irradiance, direct normal irradiance, and diffuse irradiance. The station is equipped with a solar a Kipp & Zonnen SOLYS 2 tracker with sphere shading. Two pyranometers model Kipp & Zonnen CMP6 (class B ISO-9060) are installed – one to measure global irradiance and another for diffuse irradiance. A pyrheliometer model Kipp & Zonnen CHP1 (class B ISO-9060) measures the direct normal irradiance. The data are collected using a datalogger Campbell Scientific CR1000 connected directly to a computer in which the data are stored. In addition to a solarimetric station, the laboratory also has a full weather station to generate auxiliary environmental data to determine the available solar resource. Additionally, a chamber of sky images is installed to capture the presence of clouds, as well as their formation and movement for studies of short-term solar forecasts. Prototypes of systems of solar energy use are also developed to validate numerical models developed in the laboratory.

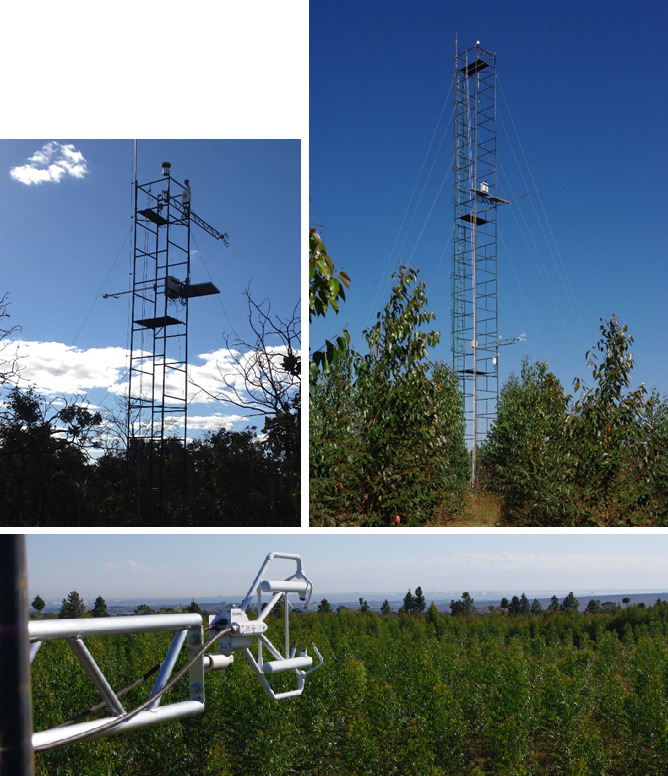

Platform Measure for Biosphere Flows – Atmosphere

The platform to measure the flows between the biosphere and atmosphere is installed at the Água Limpa Farm (FAL) of the University of Brasília, located in the Vargem Bonita Rural Center, Federal District. This platform is constituted of two flow towers, one in the native Cerrado and another in the cultivation of Eucalyptus specifically designed for this purpose. The flow towers are equipped with flow measurement systems for sensible and latent heat (evapotranspiration) and carbon dioxide flow through the vortices correlation method. Most of the main instruments were manufactured by Campbell Scientific and consist of a tridimensional sonic anemometer and a gas analyzer of fast response to measure the concentration of CO2 and water vapor. In addition to these instruments, auxiliary measures are also performed, including temperature and relative air humidity, liquid radiation exchanges (solar and thermal radiation) between vegetation and atmosphere, heat flow to the soil, moisture profile, and soil temperature. The measures are replicated in both the towers to reach a better understanding of the dynamics of mass and energy exchanges between vegetation and atmosphere, thus establishing possible meteorological/climate consequences resulting from alterations in land use with the displacement of native vegetation by other cultures, either to generate energy or produce food. These studies can support the elaboration of public policies to reduce environmental impact.

The platform to measure the flows between the biosphere and atmosphere is installed at the Água Limpa Farm (FAL) of the University of Brasília, located in the Vargem Bonita Rural Center, Federal District. This platform is constituted of two flow towers, one in the native Cerrado and another in the cultivation of Eucalyptus specifically designed for this purpose. The flow towers are equipped with flow measurement systems for sensible and latent heat (evapotranspiration) and carbon dioxide flow through the vortices correlation method. Most of the main instruments were manufactured by Campbell Scientific and consist of a tridimensional sonic anemometer and a gas analyzer of fast response to measure the concentration of CO2 and water vapor. In addition to these instruments, auxiliary measures are also performed, including temperature and relative air humidity, liquid radiation exchanges (solar and thermal radiation) between vegetation and atmosphere, heat flow to the soil, moisture profile, and soil temperature. The measures are replicated in both the towers to reach a better understanding of the dynamics of mass and energy exchanges between vegetation and atmosphere, thus establishing possible meteorological/climate consequences resulting from alterations in land use with the displacement of native vegetation by other cultures, either to generate energy or produce food. These studies can support the elaboration of public policies to reduce environmental impact.

Laboratory of Computational Science

The research work in this laboratory focuses on Computational Fluids Dynamics, with emphasis on turbulent flow through wind and hydrokinetics turbines, turbines wakes, natural channel flow (rivers), multiphase flows, and fluid-structure interaction problems. The lab is equipped with several desktop computers for scientific computation and 2 high-performance workstations.

The research work in this laboratory focuses on Computational Fluids Dynamics, with emphasis on turbulent flow through wind and hydrokinetics turbines, turbines wakes, natural channel flow (rivers), multiphase flows, and fluid-structure interaction problems. The lab is equipped with several desktop computers for scientific computation and 2 high-performance workstations.

Research line: Dynamics of Mechanical System

Laboratory of Vibrations

The Laboratory of Vibrations was built in 1982 and it is oriented to activities of teaching, research, and outreach. It has recently passed through a process of modernization and readjustment of its physical space using resources from the National Institute of Science and Technology - INCT for Smart Structures in Engineering – between 2009 and 2016 – and has continued being updated with funding granted mostly by CNPq, FAP-DF, FINEP, and Petrobras.

The laboratory has a space with workstations for undergraduate and graduate students, and an internal web of desktops and fluctuating stations. Additionally, the laboratory has several accelerometers for general and specific purposes, PCB miniature accelerometers, Baumer laser sensors for positioning, laser doppler vibrometer Polytec PDV-100, in addition to B&K microphones. It also counts with modal impact hammers with different sensitivity levels, mini hammer for light structures, and LDS and B&K shakers. The laboratory has several NI acquisition systems, signal processing & operational modal analysis software, amplifiers, and a metallurgical furnace for shape memory alloys. Over the past few years, the infrastructure available in the laboratory has enabled the performance of vibration tests, modal analysis, and the characterization of mechanical waves of light structures made of composite materials, metamaterial, and phonic crystals produced from additive manufacturing and smart materials, characterization of mechanical absorbers of vibration in elastic and pseudoelastic regime produced from shape memory alloys, tests to characterize energy harvesting in smart structures. The topics experimentally studied in the laboratory have applications mostly in the electrical energy production and transmission, oil & gas, aerospace industrial sectors. The team of the Laboratory of Vibrations has produced scientifically relevant results seeking to support the generation of innovating solutions both in the industry and society.

Research line: Fluid Mechanics of Complex Flows

Laboratory of Microhidrodynamics and Rheology – LMR

The laboratory is equipped with a rheometer coupled to a magnetic cell and microscopy with CCD camera – MCR 301 Anton Paar, a drop-pendant type Tensiometer TVT2, densimeter of samples of 2ml, state-of-art optical microscope with visualization and image analysis, and laboratory of sample preparation with ovens, precision scales, mixers, among other accessories such as gaussmeter, glassware, micrometric pipettes. The rheometer MCR 301 has a set of functions for accurate rheological characterization of a wide range of complex fluids, varying from non-Newtonian viscous fluids without memory to materials with viscoelastic properties. The laboratory develops research in complex fluids characterization (i.e. active and passive suspensions, magnetic fluids, emulsions), either at the microstructural and the rheological level. The systems tested are, in general, particulate fluids whose particles are dispersed in the fluid, such as hard spheres, drops, blisters, flexible capsules, which provides the fluid with a non-linear behavior when subjected to flows like simple or parabolic shearing. The laboratory contributes to the gathering of human resources, either at the undergraduate course (i.e. initiation to scientific research, final projects, experiments for the Fluid Mechanics discipline) and the graduate program (master and doctorate degrees) level. The laboratory also meets scientific demands from other Departments of the University of Brasília, such as Pharmacy, Chemical, Biology, and Physics.

Further information on the laboratory is available on www.vortex.unb.br.